At JetSupport, we continuously invest in technologies that strengthen the efficiency and quality of our maintenance processes. A recent innovation gaining significant traction across our facilities is the strategic deployment of 3D printing technology. By producing custom made tooling on demand, we aim to accelerate maintenance turnaround times, reduce aircraft downtime, and deliver more flexible solutions for the unique challenges our technicians face daily.

A Leap in Efficiency

Traditional aircraft maintenance relies heavily on OEM-supplied tooling, which is typically designed for broad, generic use. While functional, these tools often fall short when maintenance involves specific aircraft variants, discontinued components, or unique scenarios. In practice, the main challenges are availability and cost: lead times can extend to weeks or even months, prices are often high, and in some cases the required tool is no longer manufactured at all.

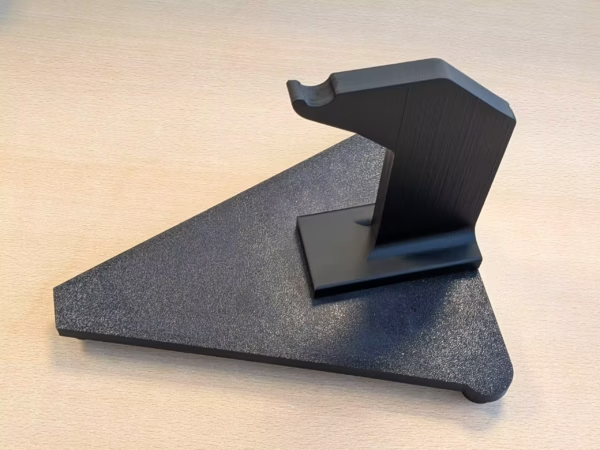

To address these limitations and improve operational flexibility, we’ve integrated 3D printing capabilities directly into our maintenance workflow. The output enables us to design, produce, and deploy specialized tooling within hours rather than weeks. For example, a custom designed support fixture for flight control balancing can be printed overnight and ready for use the following morning, making maintenance procedures more intuitive and significantly faster.

Real World Applications

We are currently deploying 3D printed tooling across multiple maintenance scenarios. Early results demonstrate substantial improvements in both efficiency and safety. Using this technology, we’ve developed practical solutions for common yet challenging tasks:

Balancing Flight Controls

Precision is critical when balancing flight controls. We’ve designed a 3D printed support fixture that holds components stable during the balancing process. The tool’s custom geometry ensures accurate positioning, accelerates the procedure, and reduces the risk of errors during this safety critical task.

Landing Gear Maintenance

During landing gear servicing, technicians often need to remove trunnion pins in confined spaces. Standard tooling is frequently oversized and difficult to maneuver. Our 3D printed alternative is lighter, ergonomically optimized, and specifically dimensioned for the actual workspace, making the procedure safer and more efficient for our maintenance teams.

Faster Turnaround, Lower Downtime

For JetSupport customers, this means their aircraft benefit from maintenance processes enhanced by purpose-built tooling that cannot be found in any catalog. This accelerates maintenance cycles, reduces delays caused by tooling unavailability, and improves overall operational reliability.

Thanks to our 3D printing capability, we can produce alternate tooling under approved procedures, ensuring compliance while addressing specific maintenance needs more flexibly. This allows us to better align our services with the demanding schedules of operators flying Dassault Falcon, Cessna Citation, Bombardier Challenger and Global, and Embraer Phenom aircraft.

The 3D printing capability is applied within our EASA, FAA, and TCCA Part-145 certified facilities at JetSupport Amsterdam, as well as at our stations in Le Bourget, Oberpfaffenhofen, and Nice.

The Advantages at a Glance

The strategic deployment of 3D printing technology delivers measurable benefits across our operations:

- Speed – Tools can be designed and produced within hours, proving crucial during AOG (Aircraft on Ground) situations where every minute matters.

- Custom Fit – Each tool is engineered specifically for the aircraft type and maintenance task, eliminating compromises inherent in generic tooling solutions.

- Cost Efficiency – Reduced dependency on external suppliers and elimination of long lead times for specialized single use tools.

- Safety Enhancement – Tools undergo iterative testing and refinement until they perform optimally, increasing the reliability and safety of maintenance procedures.

- Innovation in MRO – The application of additive manufacturing positions us as a forward thinking European MRO for Business Aviation focused on continuous improvement.

Want to Know More?

Would you like to know how we deploy this innovative technology for your fleet? Or are you curious about our capabilities for Business Jet Maintenance and custom tooling solutions for your specific aircraft type? Contact our team or discover our hangar at Schiphol.